An Essential Guide: What Printers Can Print on Pvc Cards?

Introduction

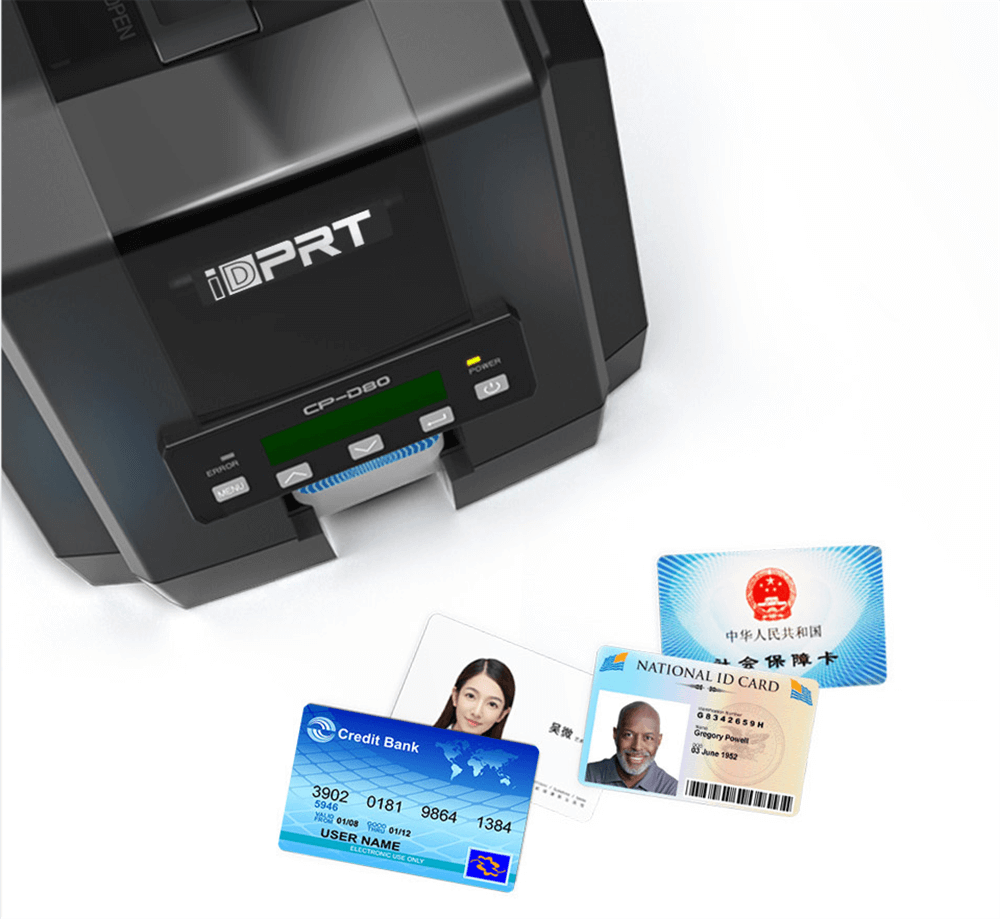

PVC cards are a popular choice for businesses and individuals alike, thanks to their durable nature and versatile uses. But when it comes to printing on these cards, not all printers are up to the task. In this article, we’ll unveil what types of printers can handle this special material, how they do it and which ones are highly recommended for the job. Our comprehensive guide is here to steer you through the world of PVC card printers and help you make informed decisions.

What are PVC Cards and Why are they Popular?

PVC or Polyvinic Chloride has become a popular material in the production of a variety of cards, primarily due to its robustness, flexibility and cost-effectiveness. Here's why PVC cards have gained such substantial traction:

• Credit Cards, ID Cards & More: These cards are essential in numerous sectors such as finance and identification. The use of PVC material, known for its sturdiness, guarantees their long-standing service.

• Exceptional Durability: PVC cards are resistant to elements such as dirt and moisture, making them an excellent choice for products that are frequently handled and need to withstand wear and tear.

• High-Quality Graphics: The ability of PVC cards to maintain high-quality graphics and color stability is an added advantage. This ensures the card's visual aesthetics remain intact over its lifespan, making these cards a preferred choice for businesses and industries worldwide.

In essence, the popularity of PVC cards hinges on their durability, versatility, and striking visual quality. With the above benefits, it's easy to see why these cards are a top pick for many.

How Do Printers Print on PVC Cards?

The printing process for PVC cards involves unique methodologies owing to the special nature of its surface. Let's delve deeper to understand how exactly printers materialize an intricate design on PVC cards.

The Underlying Printing Procedure

The fundamental process of printing on PVC cards begins with the formulation of a digital design, which serves as the blueprint of the final print. Following this, a special printer explicitly designed for PVC printing takes over to transfer this digital design onto the physical card. The efficiency and quality of the print are largely determined by the printer type.

Key Technologies Involved

- Direct-To-Card (DTC): This technology employs a print head that prints directly onto the card's surface. However, edge-to-edge printing may not be achieved due to some limitations.

- Retransfer Printing: In this process, the print is first transferred onto a clear film, which is then meticulously adhered to the card. This process results in superior image quality and allows for full edge-to-edge printing on the card.

- Thermal Transfer (Dye-Sublimation): This technology works on the principle of heating the print head, which then transfers the dye from the coloured ribbon onto the card.

Keep in mind, printers that are useful for paper printing, like the traditional inkjet printers, may not be equipped for PVC card printing. Since PVC is a non-porous material, the ink does not get absorbed, leading to subpar prints that are susceptible to damage. Thus, understanding the specific technology suitable for PVC printings is essential for achieving optimal results.

Which Types of Printers are Suitable for PVC Cards?

When it comes to printing on PVC cards, one must understand that not all printers fit the bill. It's essential to choose a printer that is specifically designed or equipped to handle such tasks. Here, we delve into the diverse types of printers that are apt for PVC cards and explore their key features and functionality.

Digging Deeper into Direct-to-Card Printers

Direct-to-Card printers, as the name indicates, print directly onto the PVC cards. These printers bring a host of benefits to the table:

- Economical: With lower costs per card, these printers are an ideal choice for budget-constrained projects.

- Speed: They are recognized for their quick print speed, which makes them suitable for projects requiring high-volume output.

- User-friendly: These printers are generally straightforward to use, making them a good option for first-time users.

- Limitation: However, they may not provide full edge-to-edge printing, leaving a small border around the card's edges.

Understanding the Mechanics of Retransfer Card Printers

Retransfer Card Printers utilize an advanced method for PVC card printing, also known as reverse transfer:

- Quality: Compared to Direct-to-Card printers, Retransfer printers offer superior print quality with sharper images.

- Versatility: They can handle uneven surfaces better due to the printing process, which involves printing onto a film that is then applied to the card.

- Full Coverage: They also provide full-edge printing, so there's no border limitation.

- Cost: However, they might be on the pricier end of the printer spectrum, reflecting the exceptional output they produce.

The Inkjet Printer Question

Inkjet printers, while popular for paper printing, do not fare well with PVC Cards:

- Surface issues: Since inkjet printers are not designed to print on non-absorbent surfaces like PVC, the end product can be sub-par.

- Durability: The print can be easily damaged or smudged due to the lack of adherence between the ink and the PVC surface.

In conclusion, although there are various printer types available, Direct-To-Card and Retransfer Card Printers are the go-to options for PVC card printing. Understanding their functionality, pros, and cons will help you make the best choice for your specific needs.

What are the Top Recommended Printers for PVC Cards

When it comes to printing PVC cards, some machines outshine others due to their superior performance, durability and exceptional features. Let's delve into the specifics of the top three recommended PVC card printers, Printer 1, Printer 2 and Printer 3.

Printer 1: Specifications and Standout Features

To start, Printer 1 is renowned for its advanced specs and key benefits. Here is a quick snapshot:

- High-Resolution Prints: It generates high-quality images with excellent resolution, ensuring sharp and clear prints.

- Speedy Performance: This printer promises quick print speed, which is perfect for high-volume projects.

- Durability: Built to last, Printer 1 is highly durable, making it an investment that can withstand heavy uses.

The Remarkable Performance of Printer 2

Next up, Printer 2 is another superior model. It surpasses expectations due to the following reasons:

- Versatility: With Printer 2, you aren't bound by limitations as it manages varying card design requirements with ease.

- Edge-to-Edge Printing: Its ability to print right up to the edges of the card ensures your complete design is displayed without any cut-offs.

- High-End Security Encoding: This advanced feature enables you to add a layer of security to your PVC cards.

Reasons to Consider Printer 3

Finally, Printer 3 is a great choice especially for smaller-scale operations. Here's why:

- Affordability: For those operating on a limited budget, Printer 3 is a cost-effective yet quality choice.

- Compact Design: Its sleek and compact design makes it ideal for places with space constraints.

- Easy Maintenance: The streamlined design of Printer 3 means you won't have to worry about complicated maintenance.

Conclusively, the ideal PVC Card printer will depend on your specific requirements and budget. Whether you opt for the high-resolution performance of Printer 1, the versatility of Printer 2, or the affordability of Printer 3, ensure you're choosing one that best fits your needs.

Conclusion

To sum up, it is essential to choose the right printer for PVC cards, taking into account the specifics of direct printing and retransfer processes. Being aware of the key features and the top printer models, you can make an informed purchase that suits your requirements.

Related FAQs about what printers can print on pvc cards

Is it Cost-Effective to Print on PVC Cards Using a Regular Office Printer?

Typically, ordinary office printers are not designed for PVC cards, resulting in inadequate adhesion of the ink to the PVC surface. This may lead to quick wear and tear of the printed design, resulting in frequent reprints and thus higher costs. Therefore, it's not cost-effective.

How to Maintain a PVC Card Printer for Optimal Performance?

To maintain a PVC card printer, it's important to clean it regularly to prevent dust accumulation. Using correct supplies like the manufacturer-recommended ribbon and cleaning kit can help in the long run. Timely updates of printer driver software also ensures optimal performance.

Can I Print on PVC Cards Using Standard Printing Settings?

Most PVC cards require specific print settings to ensure quality and durability, which usually differ from standard printer setting. Therefore, it's advised to check the printer's manual for specific PVC printing instructions or consult with its manufacturer.