Essential Sensors in 3D Printers: Functions, Types And Future Trends

Introduction

The pioneering technology of 3D printing has brought substantial changes in various sectors like manufacturing, healthcare, and design. A key enabler of this revolutionary technology's efficiency and accuracy is an array of sensors. This article will explore the essential types of sensors in 3D printers, their functions, the latest innovations in sensor technology, and future trends in this realm. Buckle up as we delve deeper into this exciting aspect of 3D printing technology.

What Are the Essential Types of Sensors in 3D Printers?

Understanding the intricacies of 3D printers involves unlocking the purpose of three critical sensor types: temperature sensors, proximity sensors, and filament sensors. Each plays a unique role in the 3D printing process:

- Temperature Sensors - Monitoring the Heat: Temperature sensors form the backbone of a 3D printer, facilitating quality prints by consistently regulating the temperature needed to accurately melt the filament. The sensor continually observes and controls the heat intensity within the extruder and the heated bed. When a temperature shift away from the desired point occurs, the sensor promptly communicates this to the printer's control system. Consequently, the Heat source's controller makes the necessary adjustments to maintain a perfect printing environment.

- Proximity Sensors - Ensuring Accurate Distances: The proximity sensors are the eyes of a 3D printer, maintaining the critical balance between the nozzle and the printer bed. They prevent the nozzle from coming too close to or touching the print bed, which could result in damage or a lesser quality print. The control system adjusts the print bed's height according to the information procured from these proximity sensors, thus ensuring a precise and seamless 3D printing process.

- Filament Sensors - Keeping a Check on Materials: Filament sensors work as diligent watchguards in a 3D printer, constantly tracking the filament's movement and availability. If the filament supply depletes or snaps, these sensors swiftly alert the system. This interruption allows the printer to pause the operation, enabling users to refill or repair the filament before the printing operation resumes. Ultimately, filament sensors contribute to a more streamlined and efficient 3D printing process.

How Do Sensors Enhance the Efficiency of 3D Printing?

Sensors in 3D printers significantly contribute to amplifying the efficiency and effectiveness of the printing process. Their impact is particularly evident in the following areas:

- Regulating Temperature for Quality: Temperature sensors are vital in upholding print quality by diligently managing the temperature required for filament melting. This kind of optimization ensures a consistent and high-quality outcome.

- Ensuring Precise Heat Control: These sensors continually supervise and adjust the heat intensity within the extruder and the heated bed. It keeps the printing environment at an optimal state, effectively avoiding adverse impacts caused by temperature discrepancies.

- Providing Crucial Data for Heat Adjustment: When any temperature deviation is detected, the sensor provides this crucial data to the printer's control system. It triggers the controller to fine-tune the heat source, maintaining the perfect balance for effective 3D printing.

In essence, sensors are the silent heroes in 3D printing technology, guaranteeing accuracy, efficiency, and top-quality results. Their impressive role in perfecting the multifaceted journey of 3D printing is truly commendable.

What Are the Latest Innovations in 3D Printer Sensor Technology?

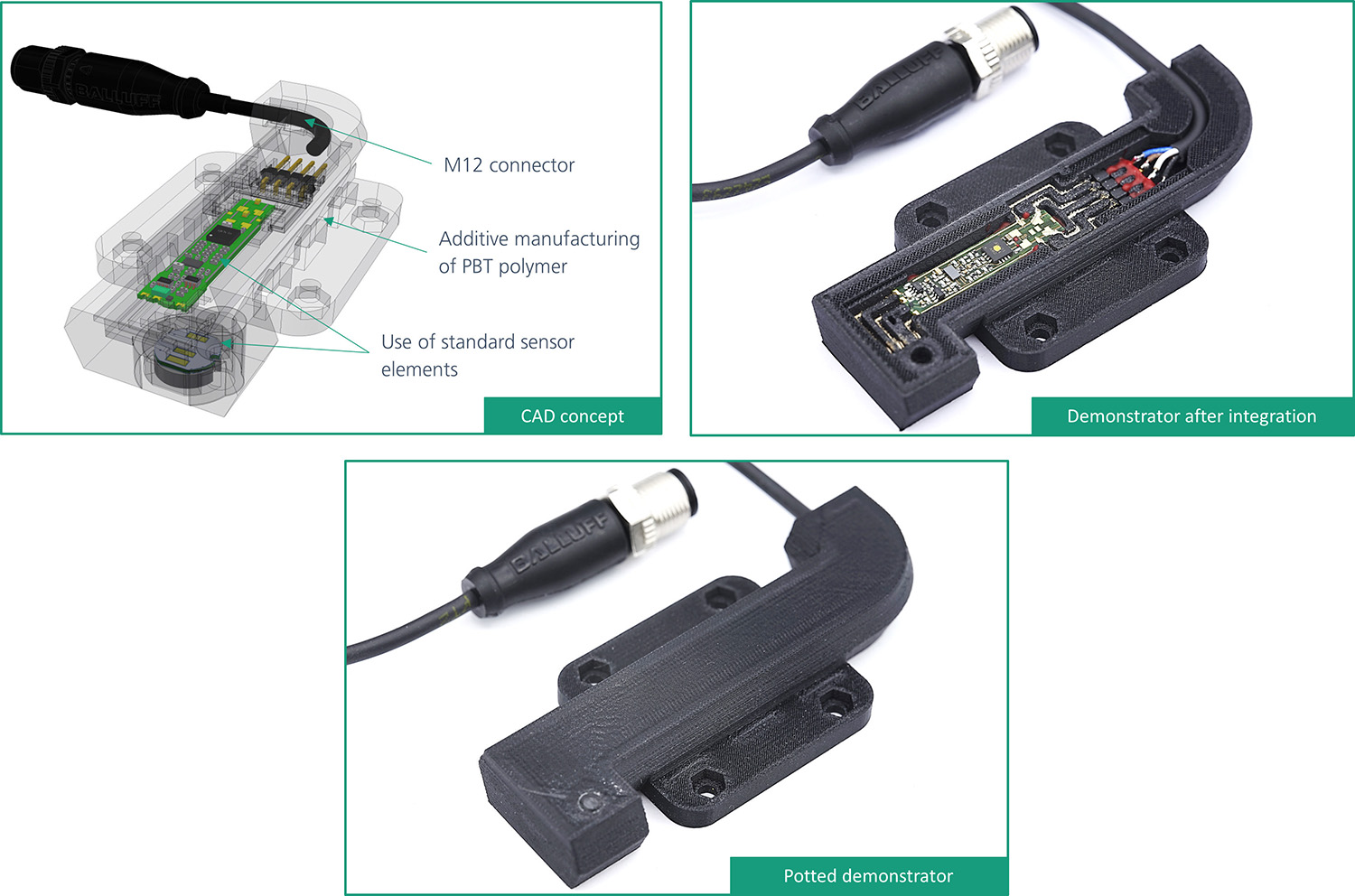

The realm of 3D printer sensor technology is constantly evolving, with intriguing advancements improving the efficiency and accuracy of 3D printers. To gain a clearer understanding, let's explore some of the latest innovations in the field:

- Advanced Temperature Sensors: Innovations have enhanced the stability and responsiveness of temperature sensors. They are now more effective at maintaining optimal printing conditions.

- Capacitive Proximity Sensors: These new types of proximity sensors offer a higher level of accuracy in detecting the distance between the nozzle and the print bed, leading to better print quality.

- Smart Filament Sensors: Technological advancements have led to improved real-time monitoring of filament availability and motion, ensuring smooth printing processes with less waste.

These technological advancements indicate great promise and potential for increasingly efficient and accurate 3D printing in the future.

What Does the Future Hold for Sensors in 3D Printing?

Looking to the future, we anticipate seeing several exciting advancements and trends in the realm of 3D printer sensor technology. Exploring these possibilities offers insights into the potential growth and evolution of 3D printing as a whole:

- Advanced Sensor Integration: There is an increasing trend towards the integration of more sophisticated sensors. These advanced sensors are expected to provide higher precision, improved quality control, and overall enhanced printer performance.

- AI and Machine Learning: With the rise of artificial intelligence and machine learning, sensors could play an essential role in predictive maintenance and process optimization of 3D printers. Through continuous data collection and analysis, they can help flag potential issues before they impact printer performance.

- Eco-Friendly and Sustainable Practices: In line with the global trend towards sustainability, we might see the development of sensors aiming to reduce waste. These could monitor filament use closely and inform users about optimal printer settings to conserve resources.

As exciting as these future trends are, they still represent just the tip of the iceberg in terms of what sensors could bring to the future of 3D printing. Stay tuned!

Conclusion

Sensors play a pivotal role in enhancing the efficiency of 3D printing by managing temperature, maintaining precise distances, and monitoring filament use. They optimize print quality, reduce waste, and minimize errors. As such, sensors are integral for consistent, high-quality 3D printing outputs.

Related FAQs about what sensors do 3d printers have

What are the most common types of sensors in 3D printers?

The most common types of sensors in 3D printers include temperature sensors, which control the temperature of the filament melting process; proximity sensors that maintain the correct distance between the nozzle and the print bed; and filament sensors, that track filament usage and alert if it's running low or snaps.

How do sensors enhance the quality of 3D printed objects?

Sensors play a crucial role in improving the quality of 3D printed objects. They ensure optimal temperature for filament melting, maintain precise distance between the nozzle and print bed for accurate layer placement, and manage filament supplies - all factors that contribute to a high-quality 3D print.

What is the role of sensors in troubleshooting a 3D printer?

Sensors provide vital information on various aspects of the 3D printing process; they can help pinpoint where a problem is occurring. For example, if a print is failing due to temperature issues, the temperature sensor data can be examined. Similarly, filament sensors can alert to filament jams or shortages.